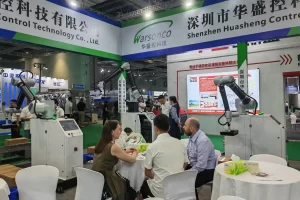

In modern manufacturing, industrial intelligence has become a key driver for improving production efficiency and quality. As a leading player in the robotics field, Warsoco is committed to providing advanced palletizing robots and parallel robots to help workers perform efficiently in various positions within factory workshops.

Warsoco’s palletizing robots are invaluable assets on automated production lines. These robots boast high speed and precision, enabling them to quickly and accurately stack and palletize products. In factory workshops, palletizing robots can replace manual labor in repetitive and labor-intensive palletizing tasks, significantly improving production efficiency and reducing costs.

Simultaneously, Warsoco’s parallel robots also play a crucial role in factory workshops. With their multiple degrees of freedom and high-speed movements, parallel robots are suitable for tasks requiring precision and rapid response. In factory workshops, these robots can be used for assembling components on assembly lines, product inspections, and other tasks, reducing the labor intensity for workers and improving production efficiency and product quality.

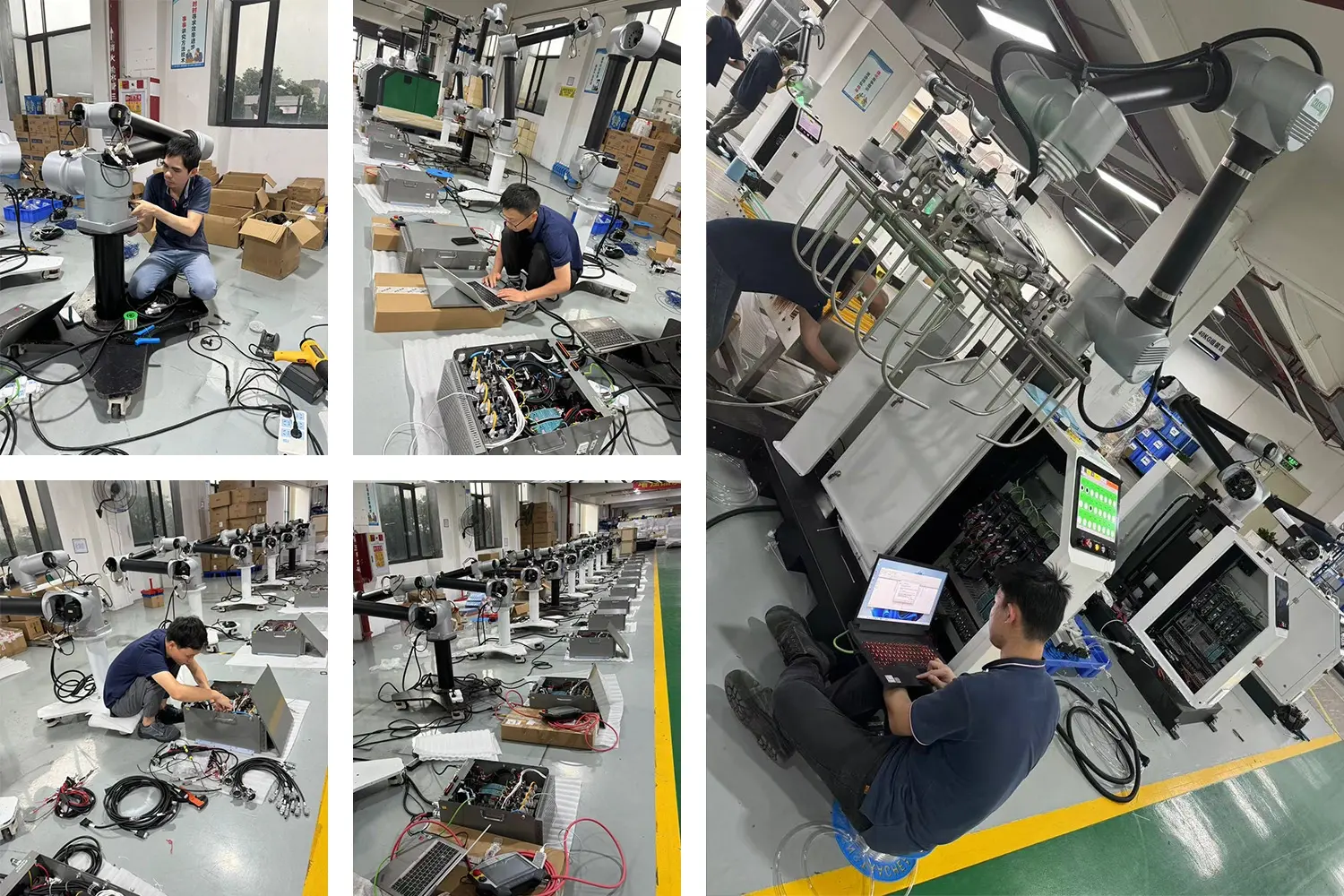

Industrial intelligence is not only reflected in the application of robots but also in production management and monitoring. Warsoco’s robots are equipped with advanced sensors and monitoring systems, allowing real-time monitoring of production line operations. This enables timely detection and resolution of issues, ensuring the stable operation of production lines.

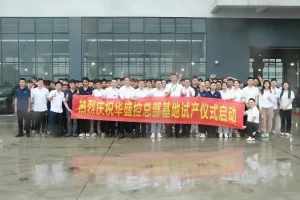

By introducing Warsoco’s robotic technology, factory workshops not only improve production efficiency and product quality but also enhance the working environment and experience for workers. In the future, Warsoco will continue to focus on developing more advanced robotic technologies, injecting new momentum into the industrial intelligence process.